RMD’s railway cameras on Wascosa’s new ballast wagon

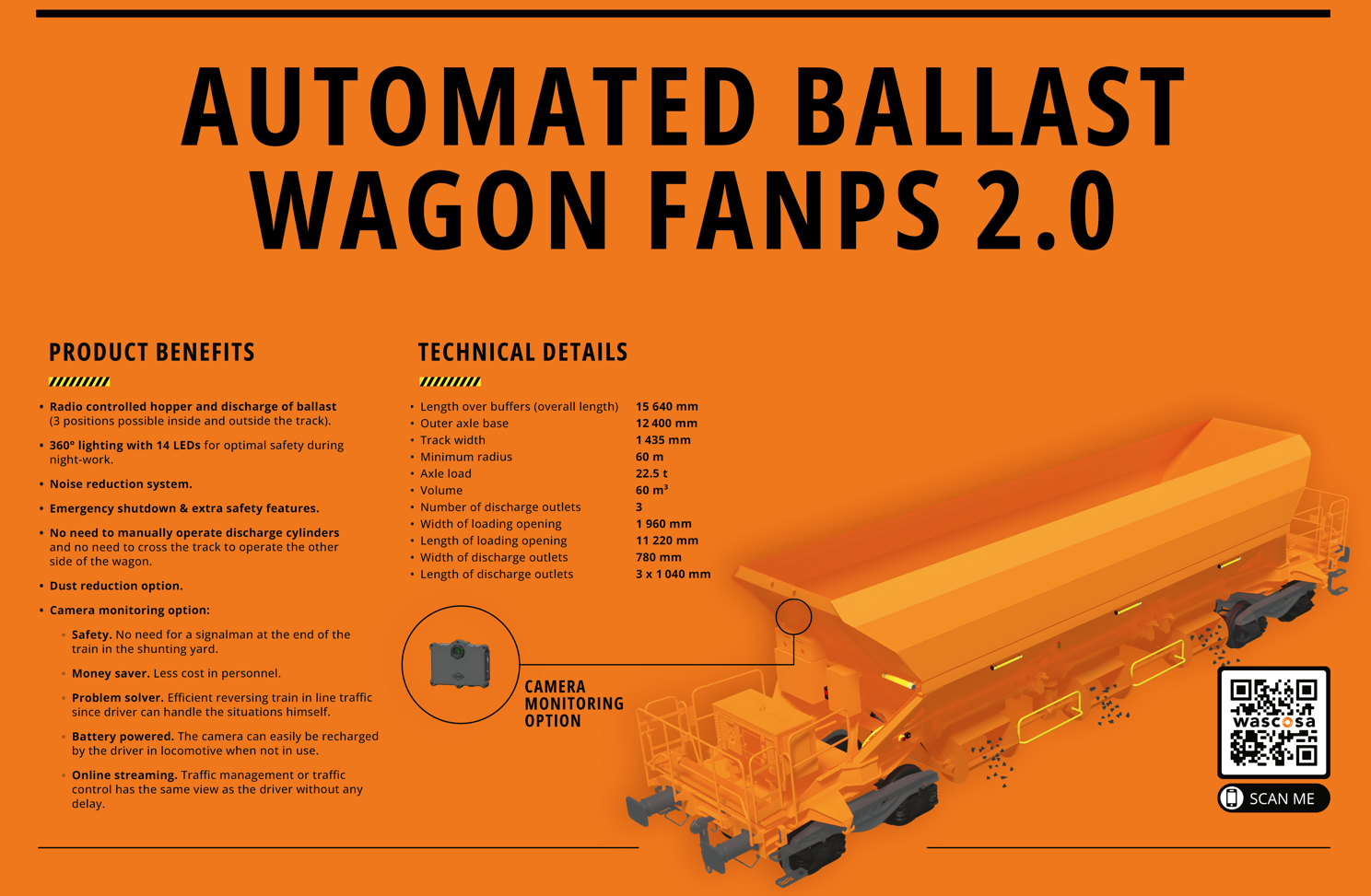

Swiss freight wagon supplier Wascosa has developed a fully automated ballast wagon for use in Europe’s growing railway construction projects. In a unique pilot project, Railway Metrics and Dynamic’s railway cameras are now being used to optimize the amount of ballast used.

In 2017, Wascosa bought 197 Fanps wagons to consolidate its position in the market for transporting ballast and other aggregates for infrastructure projects and large construction sites. However, the company soon began exploring new and more innovative applications for these wagons.

– The reason for investing in a completely new type of ballast wagon is the planned shift to rail transport that can be seen in almost all of Europe. Most countries are investing heavily in both new construction and renewal of the railway infrastructure, as this is the key to reducing CO2 emissions and making transport more sustainable, says Luc Le Formal of Swiss freight wagon supplier Wascosa.

The first wagon will be tested in a live project in France in June 2021, complete with load indicator, 360-degree lighting system, safety flashers and soundproof ballast discharge system.

– Extremely high precision is required for a good ballasting job, so one of the things we improved after the first project was the radio control system, which is now even more responsive, he says.

And now the idea is that RMD’s reversing camera will also become part of the world’s most modern ballast wagon.

– As a first step, we want to use the cameras to optimize the amount of ballast used in the field. Each tonne costs 40 euros, so there is a lot of money to be saved by being more precise, says Luc Le Formal and continues:

We see RMD’s products as very important for the performance and customer benefit of the ballast wagon.

Luc Le Formal, Wascosa

If the tests go well, Wascosa sees other applications for the camera.

– For example, customers can use the camera to check that the work is well done. It is also possible to save manpower in the field, as the cameras can see what is happening on the other side of the trailer at least as well as an additional employee.

We see great potential in the railway camera as part of our offering.

What does this mean for RMD?

– We will see after the pilot, but Wascosa has 200 wagons to rent and we expect at least 8 cameras on the test wagon, says Jan Lindqvist, CEO of Railway Metrics and Dynamics.

– We see great potential in the railway camera as part of our offering, says Irmhild Saabel, Chief Business Development Officer at Wascosa.

The pilot project began immediately after the Munich trade fair on 9-12 May, where RMD showed both the railway camera and the entire asset management platform to curious visitors.

– Several major players were present and wanted to discuss with us. Belgium’s Infrabel, for example, asked for the camera and we will give them a demonstration of the system, says Jan Lindqvist.

Need more information?

More news

RMD trains staff ahead of testing with Indonesia’s KAI

RMD has trained staff from its Indonesian partner Artindo to support the upcoming PoC with Indonesia’s KAI. The next step is a workshop with KAI in Bandung on 23 July.

RMD’s Rear-View Camera to Be Tested by US Freight Operator

RMD has delivered two test units to the United States for evaluation by a major American Class I freight railroad company. The cameras will be tested in full operation during switching work in terminal environments, with a particular focus on improving efficiency and safety.

RMD’s sensors to Indian Railways

Railway Metrics and Dynamics has signed an agreement with JK Exim for the testing and evaluation of PMU sensors with state-owned Indian Railways.