The Performance Monitoring Unit

– at the heart of everything

The PMU is an advanced unit that registers vibrations and various types of anomalies in the interaction between railway infrastructure and rolling stock. The PMU maintains constant connection with RMD’s AI- and Machine Learning-based system platform – a platform that continuously learns and improves as more data is reported. Via the PMU, the system warns about for negative trends, alerts critical faults, and can indicate when maintenance may be needed. It is at the very heart of our “system-of-systems”.

What is a Performance Monitoring Unit?

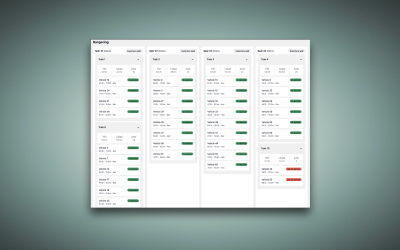

The PMU sensors are smart devices that detect an extensive array of faults and potential problems. They collect and analyse recorded vibration data and communicates with RMD’s cloud. The data and analysis can then be visualized on a dashboard in RMD’s proprietary Train Management System.

Digitalization provides full control

The PMUs are ready as soon the locomotive starts. This way, you always know how many hours the rolling stock has been in use, which is crucial for performing scheduled maintenance. During shunting and terminal operations, it is especially valuable that the PMUs also register and log impacts from careless loading or overloading.

Derailment detection

The PMU instantly detects a derailment. An alert message is sent to the train driver via the MyTrain app. The driver can immediately take action and stop the train, keeping the damage to infra structure and rolling stock to a minimum. Repairs can be carried out in significantly less time and the line can be re-opened much sooner.

Measures acceleration and registers location

The Performance Monitoring Unit (PMU) is easily mounted on the side of a wagon or a locomotive. A GPS within the PMU keeps track of the location. Accelerometers within the PMU measures the acceleration profile (the vibrations) that is generated when the train runs along the track.

Predicts arising faults and diagnoses status

The PMU analyses the acceleration profile and determines if it is normal, or if the profile has an anomaly due to an arising fault. The PMU uses AI, machine learning and sophisticated algorithms to on the acceleration profiles to identify where the anomaly originates from (infrastructure or train) and exactly which fault that is about to arise.

The machine learning part av the system sends the data to the cloud through a mobile internet connection, where further monitoring and analyses are conducted with advanced algorithms.

Warns about defects and negative trends

If an anomaly emerges in the acceleration profile, an alert is sent in real-time to the user interface such as the dashboard. The data can also be delivered to external systems if necessary.

If the fault is acute, a warning is also sent directly to the train driver through RMD’s app “My Train”. The train driver is then instantly alerted and can stop the train immediately, thus minimizing the damage and repair time.

The system also alerts for damages that has emerged on a specific place in the track since the previous time the PMU passed by.

The PMU monitors:

- Track health

- Ride dynamics

- Wheel flats

- Temperature variations in wheel boxes

- Derailment detection

- Geofencing

- GPS tracking

- Trends

- Driver behaviour

- Ride index

- Track setting

- Instability

- And much more!

The PMU detects a large number of faults

RMD’s monitoring system detects and identifies a large number of faults within both the rolling stock and the infrastructure.

Train status:

- Derailment detection

- Abnormal wagon behaviour

- Wheel flats (wheels deformed by friction)

- Instability

- Frozen brakes

- Broken springs

- Thin wheel flanges

- Estimate of time to wheel change and wheel turning can extend life by 50%

- Maintenance warning for wheels, springs and bogies

- Security warning for reduced speed and emergency stop

- Trailer fastening safety system (Kingpin Lock)

Infrastructure:

- Broken rail

- Heat distortion

- Abnormal turnout function

- Track cracks

- Signal failures

- Power lines

Positioning:

- Traceability

- Inventory control

- Geofencing

- Wagon registration

Need more information?

Related articles

Pantograph Sensor

The pantograph sensor monitors trends and deviations and sends data to be processed by RMD's machine learning algorithms. It registers any potential faults or errors of the pantograph itself - as well as any potential damage to both the carbon rail and the copper line.

Digital Shunting Tool

RMDs digital shunting tool is based on equipping wagons with PMUs and serves as a tool to help customers move away from the manual handling still in use. The train dispatcher can assemble new train sets using the ”drag-and-drop” functionality.