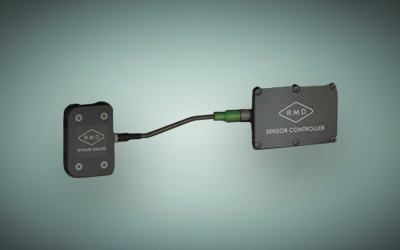

Pantograph Sensor

The Pantograph Sensor performs just like a normal PMU, but is designed for being attached to the pantograph. The pantograph sensor monitors trends and deviations and sends data to be processed by the machine learning algorithms. It registers any potential faults or errors of the pantograph itself – as well as any potential damage to both the carbon rail and the catenary line.

The data is processed in real-time, and the system carefully monitors the status of both infrastructure and locomotive components, which in turn enables preventative measures. Damages to the catenary line or the carbon fiber rail can result in the patograph getting caught, resulting in catastrophic tear-down of the catenary lines. If a failure should occur, the train driver is alerted instantly via the “MyTrain” app, and can stop the train to prevent further damage.

Features

- Monitors status of pantograph

- Monitors status of catenary lines

- Real-time monitoring

- Alerts driver via MyTrain-app

Need more information?

More products from RMD

Load Weight Sensor

The Load Weight Sensor registers the cargo weight and also makes sure that the load is evenly distributed. This relieves rail and infrastructure from uneccessary stress and makes sure that the cargo weight is reported automatically and correctly to Topas or other systems.

Kingpin Lock Sensor

The Kingpin Lock sensor constantly monitors the kingpin lock to ensure that it is properly engaged at all times. The kingpin lock is a crucial component that prevents cargo trailers from separating during transit.