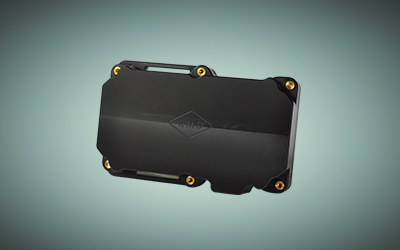

Load Weight Sensor

The patented Load Weight Sensor registers the cargo weight and also makes sure that the load is evenly distributed. This relieves rail and infrastructure from unneccessary stress and makes sure that the cargo weight is reported automatically and correctly to Topas or other systems. It is part of the RMD system for “Automatic Train Departures” (ATD).

Uneven loading and truck hunting

Uneven load distribution in freight rail operations can create excessive forces that contribute to truck hunting. When a rail car is imbalanced, its center of gravity shifts, increasing lateral forces on the track. This can cause the wheelsets to move erratically from side to side, leading to increased wear on both wheels and rails. Additionally, an imbalanced load makes the rail car more prone to oscillations, which can further affect ride stability, especially at higher speeds.

It also leads to an impaired suspension response: Rail cars are designed to handle weight within certain limits on each axle. Uneven loading places extra stress on the suspension, which may not absorb lateral forces as effectively, leading to poor stability.

There is also a risk of resonant oscillations: If the load is off-balance, small oscillations can be amplified into more severe truck hunting. Once this motion begins, it’s difficult for the suspension system to counteract, especially in freight cars lacking advanced damping systems.

Rough loading

Besides registering the weight and its distribution, the load weight sensor from RMD also monitors the loading process itself – registering any improper handling.

Automatic Wagon Registration

Weight sensors for railways offer many advantages. Before a freight train can depart, a wagon inspection must be conducted. This involves documenting the type of wagons in the train set, how much the load weighs, and the position of each wagon in the train set. This is collectively known as “train composition.”

In Sweden, the train composition and weights must be reported to the Swedish Transport Administration via the Topas system. Currently, this reporting is done manually – either through an application or via a third-party interface and Common Interface.

Since the RMD weight sensors knows the position of a wagon within a train set, it can handle both the wagon inspection and reporting entirely automatically, eliminating the risk of human error. The sensor is part of the RMD concept “Automatic Train Departures” (ATD) – aiming to increase the capacity of the entire Swedish railway system by allowing for more frequent departures.

Accuracy

Weight restrictions are crucial. Different wagons have different load capacities and loads of varying density, and different track sections have specific limitations. Accurate weight calculation is necessary, and the human factor poses a risk for incorrect estimations. With the RMD weight sensor, wagons can be weighed with precision, which is significant since track fees are based on weight.

Advantages

- Correct cargo weights

- Uneven loading alert

- Rough loading alert

- Correct track fees

- Saves suspension

- No resonant oscillations

- Less track hunting

- Part of ATD-system

Need more information?

More products from RMD

Performance Monitoring Unit

The PMU is a state of the art sensor for digitalizing railways. It is an extremely competent unit, capable of detecting and recognizing almost every anomaly in railway infrastructure and rolling assets.

Pantograph Sensor

The pantograph sensor monitors trends and deviations and sends data to be processed by RMD's machine learning algorithms. It registers any potential faults or errors of the pantograph itself - as well as any potential damage to both the carbon rail and the copper line.