Automatic Train Departures (ATD)

Automatic Train Departures (ATD) is a concept that automates certain processes that are often handled manually during departures from railway terminals and marshalling yards. The goal is to streamline terminal operations, reduce human errors, and increase freight train capacity.

About our sensors and ATD system

ATD offers several advantages, particularly when railway capacity is under pressure, as the technology helps increase efficiency without requiring significant infrastructure investments.

With Railway Metrics’ sensors and ATD system, it is possible to:

- Automatically measure wagon weights, with data directly reported to systems such as the European system Topas.

- Automatically collect data on train composition and condition, ensuring faster departures with accurate information.

- Reduce the need for manual tasks such as walking along the train to estimate weight and wagon status.

- Improve safety by minimizing human errors.

- Gain better situational awareness and make faster decisions.

- Save costs by ensuring correct infrastructure charges are paid.

- Reduce operational disruptions.

- Minimize train downtime.

- Optimize resource use by reducing the need for extra personnel at terminals.

How RMD’s Automatic Train Departures solution works

A wagon intake process contains a wealth of information about a train, including EVN numbers, technical data, freight weights, wagon weights, total weight, UN numbers for hazardous goods, route details, and the individual positioning of wagons. Today, this is a time-consuming process with a risk of manual errors.

“Automatic Train Departures” (ATD) from Railway Metrics and Dynamics consists of two main components:

- The first involves using sensors to ensure comprehensive data collection for each individual wagon and the train composition as a whole.

- The second involves digitizing and automating the process that currently requires manual entry of wagon intake data (in Topas or via a third-party program connected to Common Interface).

With ATD, we combine load weight sensors and PMUs (Performance Monitoring Units) to fully automate wagon intake and reporting to Topas. The result? Faster processing, more accurate data, and more efficient use of resources such as locomotives, wagons, and marshalling yards, while also reducing maintenance requirements.

ATD from Railway Metrics and Dynamics enables faster train preparation for departure with a lower risk of errors and better resource optimization.

This paves the way for shifting more freight transport from roads to railways.

In brief:

- Automatic weights registration

- Automatic data reporting

- No human estimates

- Improved safety

- Better situational awareness

- Faster decision-making

- Correct infrastructure charges

- Less disruptions.

- Minimized train downtime.

- Optimized resource use

Presentation (hover to pause)

The effect: More freight on rail

By automating the registration of wagon weight and positioning within the trainset, we save both time and resources. Manual data entry is eliminated, and shunting work can sometimes be reduced from two hours to just 15 minutes – an efficiency gain of 87.5%.

More efficient workflows allow freight trains to depart terminals faster and prevent unnecessary congestion on shunting tracks. This means more departures can be scheduled with fewer resources, increasing capacity for intermodal transport and shifting more freight onto rail.

Today, weight data is based on manual estimates, which can easily lead to miscalculations. For instance, it is difficult to estimate the weight of timber or recycled metal – and even harder to determine whether the load is evenly distributed. With ATD, precise information is obtained every time, making transport safer and more efficient.

Accurate weight data allows for optimized use of wagons, reducing unnecessary wear and keeping maintenance needs low. Additionally, track access charges can be based on precise weights rather than estimates, which often lead to higher-than-necessary fees.

By optimizing the number of wagons based on locomotive traction capacity, more freight can be transported by rail. Increased efficiency also allows for denser traffic, further improving system capacity.

Real-time data from the PMU also provides the ability to react quickly to disruptions or incidents. If an issue arises, the train can be moved aside without affecting other traffic – a crucial factor in keeping the system running smoothly and ensuring maximum capacity utilization.

Need more information?

Related articles

Digital Shunting Tool

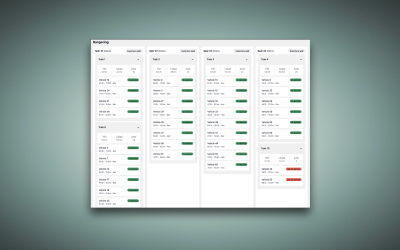

RMDs digital shunting tool is based on equipping wagons with PMUs and serves as a tool to help customers move away from the manual handling still in use. The train dispatcher can assemble new train sets using the ”drag-and-drop” functionality.

Temperature Sensor

The temperature sensitive bolts in our system solution work in conjunction with PMU sensors. The bolts send their information to nearby PMUs, which act as communication hubs between the smart bolts and RMDs system plattform.

Pantograph Sensor

The pantograph sensor monitors trends and deviations and sends data to be processed by RMD's machine learning algorithms. It registers any potential faults or errors of the pantograph itself - as well as any potential damage to both the carbon rail and the copper line.

All rights reserved